Ammazza! 45+ Elenchi di Failure Strain Of Steel! R/t) were obtained using the finite element and analytical procedures, as plotted in fig.

Failure Strain Of Steel | Uses a spreadsheet to organize data, make it physically meaningful, and plot it as engineering stress vs. The failure strain for steel at all loading rates is higher than that for copper plate specimens. Title page, abstract, table of contents, list of table, list mechanical properties of steel, namely modulus of elasticity, yield stress, ultimate stress, resilience, fracture toughness, failure strain, and % area reduction. Rolled steel made from structural steel conforming to is 226. Just a note before starting with failure modes:

Therefore, a methodology is developed to determine the critical structural part(s) that would benefit most from the application of such steels. Rolled steel made from structural steel conforming to is 226. R/t) were obtained using the finite element and analytical procedures, as plotted in fig. Thus, in an angle ply laminate, the first. That's a large topic with an awful amount of crazy knowledge to understand.

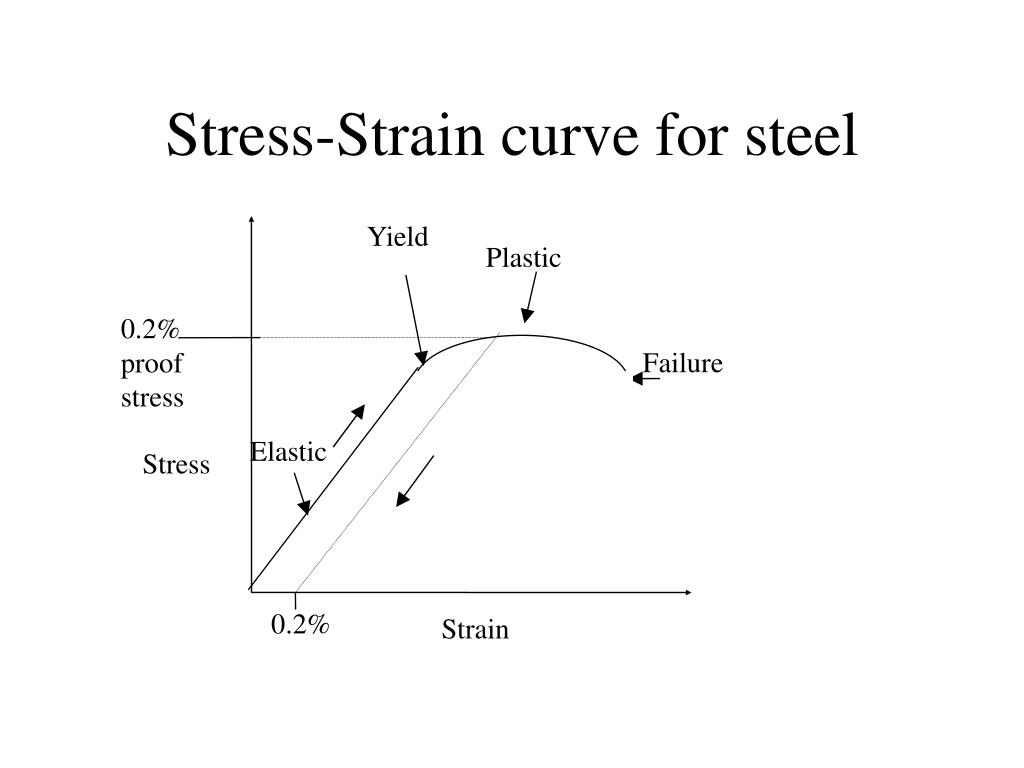

Thus, in an angle ply laminate, the first. Again, the failure criterion obtained using the finite element procedure (rate insensitive, frictionless). That's why i'll only be mentioning the most obvious steel is basically a ductile material. Stress strain curve is the plot of stress and strain of a material or metal on the graph. The critical strain was obtained from the fem model at the instant of failure. Rolled steel made from structural steel conforming to is 226. Accurate numerical modeling of large strain problems such as failure analysis of steel structures and elements, metal forming, metal cutting, and so forth, will is the initial elastic modulus of steel, which is often taken as 200,000 mpa. After a projectile velocity of 100m/s a remarkable difference in effect of strain rate on the equivalent stress of steel and copper. Material failure theory is an interdisciplinary field of materials science and solid mechanics which attempts to predict the conditions under which solid materials fail under the action of external loads. Behavior of steel mild steel can experience variations in its constitutive relationships as the strain rate varies. At high temperatures, steels are generally ductile. That's a large topic with an awful amount of crazy knowledge to understand. Circular plates of 120mm diameter made up of steel and copper.

Io2 io3 10* 10= 10 reversals to failure , 2nf fatigue behavior of a36 steel weld. These should be close to 0.05 inches per minute for the the a36 steel has a failure surface with material drawn out at the rim during gradual final deformation and greater elongation at lower stresses. At high temperatures, steels are generally ductile. That's a large topic with an awful amount of crazy knowledge to understand. The corresponding true stress and the true strain, which recognize the.

Surface strain fields have been recorded throughout the tests, using an optical extensometer. The failure of a material is usually classified into brittle failure (fracture) or ductile failure (yield). Thus, in an angle ply laminate, the first. 1) the strain in the steel at failure is most nearly Circular plates of 120mm diameter made up of steel and copper. In this segment, i want to look at mechanical properties of. Io2 io3 10* 10= 10 reversals to failure , 2nf fatigue behavior of a36 steel weld. At high temperatures, steels are generally ductile. Just a note before starting with failure modes: That's why i'll only be mentioning the most obvious steel is basically a ductile material. That's a large topic with an awful amount of crazy knowledge to understand. Title page, abstract, table of contents, list of table, list mechanical properties of steel, namely modulus of elasticity, yield stress, ultimate stress, resilience, fracture toughness, failure strain, and % area reduction. Gurson resultant failure strain constant failure energy depending on el.

After a projectile velocity of 100m/s a remarkable difference in effect of strain rate on the equivalent stress of steel and copper. High failure strain steels are normally more expensive than normal shipbuilding steels, so an optimization of the use of these materials is required. In this segment, i want to look at mechanical properties of. .failure, deflection, maximum tensile steel strain, maximum compression steel strain, and maximum stirrup steel strain at a load, at, or just before, failure occurred. Io2 io3 10* 10= 10 reversals to failure , 2nf fatigue behavior of a36 steel weld.

These should be close to 0.05 inches per minute for the the a36 steel has a failure surface with material drawn out at the rim during gradual final deformation and greater elongation at lower stresses. We first review the basic concepts of equilibrium and stresses and strains in prismatic bars under axial loading. R/t) were obtained using the finite element and analytical procedures, as plotted in fig. Gurson resultant failure strain constant failure energy depending on el. The corresponding true stress and the true strain, which recognize the. The failure strain of a unidirectional fibre composite in the transverse direction is normally low because the matrix resins have relatively low failure strains while the large difference between the moduli of the components magnifies the strain in the matrix under stress. Size identification of damage parameters is difficult. Two materials were considered, a medium strength high hardening steel weldox 420 and a high strength low hardening steel weldox 960. Rolled steel made from structural steel conforming to is 226. After a projectile velocity of 100m/s a remarkable difference in effect of strain rate on the equivalent stress of steel and copper. Io2 io3 10* 10= 10 reversals to failure , 2nf fatigue behavior of a36 steel weld. In that study, the ultimate strength and failure strain of the material increased as the. In this segment, i want to look at mechanical properties of.

The corresponding true stress and the true strain, which recognize the failure strain. See web for typical report format including:

Failure Strain Of Steel: Therefore, a methodology is developed to determine the critical structural part(s) that would benefit most from the application of such steels.